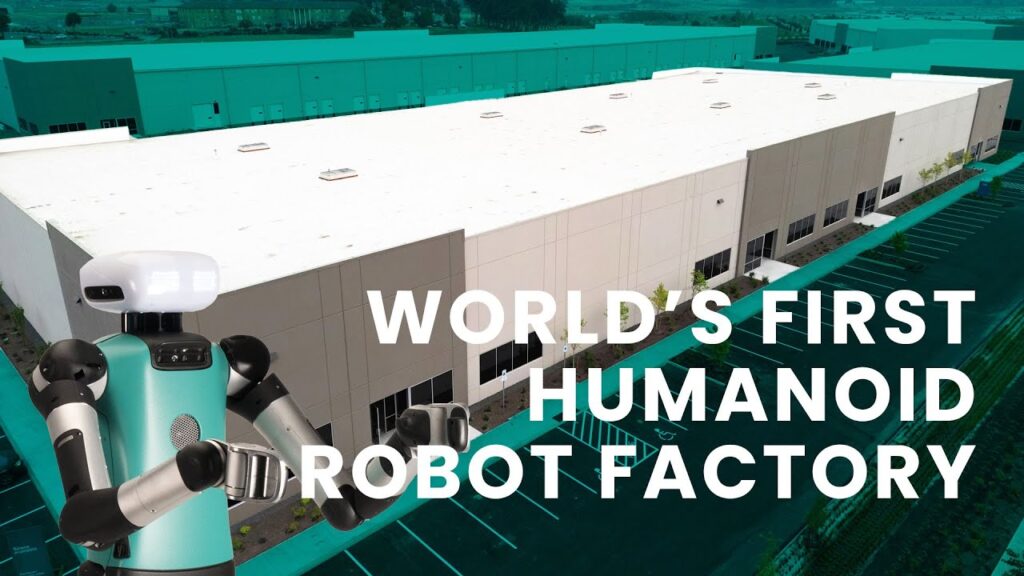

RoboFab, developed by Agility Robotics, is an advanced robotic production facility designed for mass manufacturing of humanoid robots. It aims to produce over 10,000 robots annually, marking a significant milestone in the robotics industry.

Addressing Workforce Challenges

The primary goal of RoboFab is to address workforce challenges in various industries. Humanoid robots can mitigate issues like injuries, burnout, high turnover rates, and labor shortages by enhancing productivity and efficiency through advanced technology and artificial intelligence.

Technological Advancements in RoboFab

Advancements in Design

RoboFab focuses on creating humanoid robots with advanced designs that closely resemble humans. These robots possess features such as facial expressions, body movements, and gestures, enabling more intuitive and natural interactions with humans.

Integration of Artificial Intelligence

Humanoid robots from RoboFab are integrated with artificial intelligence (AI), allowing them to learn and adapt to different environments and tasks. This versatility makes them suitable for a wide range of complex activities across various industries.

Mobility and Dexterity

RoboFab emphasizes improving the mobility and dexterity of humanoid robots through advanced limb technologies. This enhancement enables them to navigate diverse terrains and execute precise tasks, making them valuable in healthcare, manufacturing, and customer service.

Mass Production’s Significance

Addressing Workforce Challenges

Mass production of humanoid robots addresses workforce challenges by reducing injuries from strenuous tasks, minimizing employee burnout, curbing high turnover rates, and filling labor gaps in specific industries. Robots excel in repetitive, strenuous, or hazardous tasks, reducing associated risks.

Meeting Market Demand

The increasing demand for automation and robotics necessitates mass production to cater to market needs. RoboFab’s scalability and efficiency enable businesses to adopt automation on a larger scale, contributing to overall economic growth.

Potential Industry Applications

Mass-produced humanoid robots find applications in healthcare, manufacturing, and customer service. They can assist in patient care, optimize manufacturing processes, and enhance customer experiences, revolutionizing these industries.

Inside RoboFab’s Factory

Factory Location and Size

RoboFab’s factory spans 70,000 square feet in Salem, Oregon, demonstrating the company’s commitment to delivering high-quality humanoid robots.

Construction Timeline

Construction commenced last year, with the factory expected to open later this year. This timeline underscores the company’s dedication to accelerating mass production.

Manufacturing Process

A video released by Agility Robotics showcases the manufacturing process at RoboFab, providing insights into stages like assembly, testing, and quality control.

Digit’s Role in RoboFab

Introduction to Digit

Digit, a bipedal humanoid robot developed by Agility Robotics, plays a significant role in mass production at RoboFab. Its advanced technology and capabilities serve as a model for other robots produced within the facility.

Digit’s Contribution

Digit assists in tasks like assembly, quality control, and packaging, streamlining production and ensuring high-quality robots. Its mobility, dexterity, and AI capabilities enhance efficiency and productivity.

RoboFab’s Impact on the Robotics Industry

Revolutionizing the Industry

RoboFab’s mass production of humanoid robots can revolutionize the robotics industry by promoting widespread automation, increasing productivity, and reducing costs. This shift could redefine traditional manufacturing processes and foster innovation.

Disruption and Job Impact

While automation benefits industries, it raises concerns about job displacement. Certain roles may become obsolete, necessitating skill adaptation. However, robots can often complement human labor, creating new employment opportunities in robot management and maintenance.

Ethical Considerations

Deploying humanoid robots raises ethical concerns regarding privacy, data security, and their ethical treatment. Establishing guidelines and regulations is crucial to ensure responsible robot use, considering their impact on individuals and society.

Applications of Humanoid Robots

Healthcare and Medical Fields

Humanoid robots excel in healthcare, assisting professionals in patient care, movement assistance, and basic medical procedures. They can also enable remote monitoring and telemedicine, providing quality healthcare access to underserved areas.

Manufacturing and Assembly

In manufacturing, humanoid robots optimize assembly lines, enhance efficiency, and reduce errors. They handle repetitive, strenuous, or hazardous tasks, allowing human workers to focus on complex aspects. Collaboration between humans and robots also improves productivity.

Customer Service and Hospitality

Humanoid robots have the potential to transform customer service and hospitality by offering personalized assistance, answering queries, and providing services like housekeeping and concierge. This enhances customer experiences and operational efficiency.

Future Developments and Possibilities

Enhanced Human-Robot Interaction

Advancements in natural language processing, gesture recognition, and facial expression analysis promise more seamless human-robot interactions. Robots may better understand human emotions, preferences, and intentions.

Integration with IoT

Integrating humanoid robots with the Internet of Things (IoT) enables automation and connectivity. Robots can access and analyze data, making informed decisions and performing tasks more efficiently.

Personal Use Potential

As production costs decrease, humanoid robots could find applications in personal settings. They might assist with home tasks, provide companionship, and offer entertainment, transforming households and individuals’ daily lives.

Challenges and Limitations of Mass Production

Cost Considerations

Mass production entails substantial costs for facility development, maintenance, and robot quality assurance. However, economies of scale and manufacturing advancements are expected to reduce overall production costs.

Safety and Security Concerns

Ensuring humanoid robot safety and security is crucial as they interact with humans and operate in various environments. Risk assessments, safety protocols, and secure software systems are essential to minimize risks.

Regulatory and Legal Implications

Mass production and deployment of humanoid robots necessitate regulations concerning safety standards, privacy, data protection, and liability. Governments and regulatory bodies must establish guidelines to ensure responsible and ethical practices.

Conclusion

RoboFab’s mass production of humanoid robots represents a significant advancement in the robotics industry. These robots have transformative potential across industries, but ethical considerations, job impacts, and regulatory guidelines must be carefully addressed. Balancing automation advantages with responsible practices will ensure that humanoid robots positively impact society, fostering progress, productivity, and innovation.